Beginners Guides

Revolutionizing Coffee Production: Exploring The Latest Technology Trends

As a coffee production technology expert, I have some exciting news to share! The latest trends in coffee production are revolutionizing the industry and making it easier than ever to provide quality, fresh coffee. From automated roasting machines to remote monitoring technology, this cutting-edge technology is sure to make a difference in the lives of those who serve others coffee.

In this article, I’ll explore the latest trends in coffee production technology that are transforming the industry. From improved efficiency and cost savings to greater consistency and flavor profile control, these innovative tools can help increase customer satisfaction and build your business. I’ll also discuss how you can use these new technologies to better serve your customers.

So let’s dive into revolutionizing coffee production by exploring the latest trends in technology! With these powerful tools, we can create amazing experiences for our customers and ensure they receive top-notch service every time. Whether you’re just getting started or looking for ways to take your business to the next level, this article has something for everyone.

What Is Coffee Production?

Coffee production is nothing short of revolutionary! Every sip of coffee we take is the result of a complex, multi-step process that starts with harvesting and ends with packaging. From coffee harvesting to coffee roasting, grinding, brewing and packaging – it takes an incredible amount of skill, knowledge and technology to ensure each cup is enjoyed exactly as intended.

The world’s most renowned coffee producers are constantly innovating in order to stay on top of the game. New trends in coffee production technology have allowed for unprecedented levels of precision, quality control and efficiency – resulting in a superior cup every time. Automation has taken over manual processes, allowing for a faster turnaround time for large batches and consistent quality across the board.

The digital transformation of the coffee industry has profoundly affected how we produce our favorite beverage. With new technologies coming into play daily, there are exciting opportunities to revolutionize how we make coffee at home or enjoy it out on the town. Let’s explore some of these cutting-edge trends that are transforming coffee production!

Digital Transformation Of The Coffee Industry

The digital transformation of the coffee industry has been a long time in the making. With advances in technology, we have seen leaps and bounds in improvements to production automation, quality control, and overall efficiency. Here are some of the key trends that are revolutionizing the way coffee is produced:

- Automation: Automation technology is being used to streamline production processes and reduce manual labor costs. This includes robotic arms for sorting beans, machines for roasting coffee beans, and automated packaging systems.

- Quality Control: Quality control systems allow producers to track their products from seed to cup with precision and accuracy. This ensures that each batch of coffee is consistent and meets quality standards every time.

- Connectivity: Coffee producers now have access to real-time data that can help them make better informed decisions about production schedules, product quality, and more. This helps them stay ahead of industry trends and remain competitive in an ever-changing market.

These three trends are driving the digital transformation of the coffee industry, allowing producers to produce higher quality products at a fraction of the cost compared to traditional methods. As this trend continues, we can expect even more improvements in productivity and efficiency as automation technologies become more advanced.

Automation Technologies

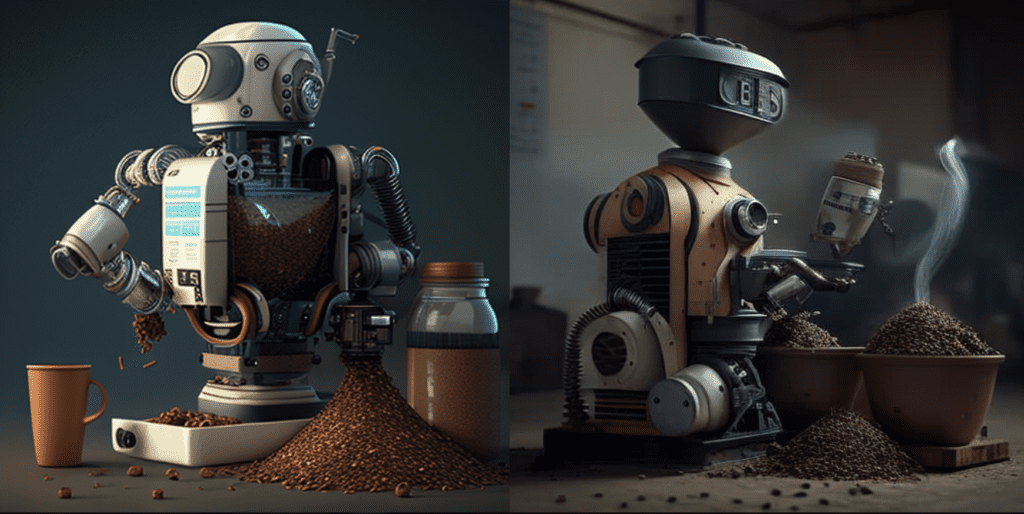

The coffee industry is undergoing a digital transformation. Automation technologies are proving to be an essential part of this evolution. From robotic automation to machine learning and predictive analytics, coffee producers can now make decisions in real-time, revolutionizing their production process.

Robotic automation is one of the most exciting developments in the coffee industry. Robots are able to quickly and accurately perform tasks that used to require manual labor, saving time and money for producers. This technology can be used for everything from harvesting and sorting beans to packing them into bags for shipping. It’s also being used to help with quality control, ensuring that only the highest-quality beans reach consumers.

Machine learning and predictive analytics have become increasingly important as well. These technologies enable producers to analyze data more quickly and accurately than ever before, allowing them to make more informed decisions about production processes and pricing strategies. Furthermore, they can use these insights to develop new products or services that cater specifically to consumer needs.

This is just the beginning of how automation technologies are revolutionizing coffee production. As we move forward, we can expect even more advances in robotics and artificial intelligence in production processes, further streamlining operations while still delivering high-quality products at an affordable price point.

Robotics And Artificial Intelligence In Production

Using robotics and artificial intelligence (AI) in production processes is revolutionizing the way coffee is produced. By automating many of the labor-intensive tasks associated with its production, AI technology has enabled more efficient processes and higher levels of quality control.

Robotics can be used to automate repetitive tasks such as picking and sorting, while AI technology can monitor and analyze each production stage. This helps reduce waste, increase yields, and improve product consistency. Additionally, machine learning algorithms can detect anomalies and make predictions that enable faster corrective action.

Benefits Challenges Automation of mundane tasks High cost of implementation Improved production efficiency Complexity in programming robots Higher quality control Safety concerns for personnel around robots/AI systems Faster corrective actions based on data-driven insights Risk of over-automation or redundancy in certain areas

The integration of robotics and AI into coffee production processes is a promising development that could result in improved efficiency, better quality control, and cost savings for coffee producers. As these technologies continue to evolve, it will become increasingly important for coffee producers to stay up-to-date with the latest advances in order to remain competitive. This makes data-driven production and quality control a critical strategy for achieving optimal results in today’s ever changing coffee industry landscape.

Data-Driven Production And Quality Control

Let’s dive into the world of data-driven coffee production and quality control. Achieving efficiency and quality assurance are key goals in this domain. By leveraging data analytics, machine learning, and predictive analytics, we can optimize our production processes to make sure that we’re producing the highest quality coffee at the lowest cost.

Data collected from production machines allows us to identify bottlenecks and potential issues before they become costly errors. We can use this data to adjust our production parameters to ensure that every cup of coffee is brewed just right. Additionally, by tracking customer feedback over time, we can identify trends in tastes and preferences so that our products are always tailored to meet the needs of our customers.

Quality assurance is also enhanced through automated systems. Machine learning algorithms can be used to detect defects or inconsistencies with product specifications quickly and accurately so that corrective action can be taken immediately. This ensures that all products meet customer expectations while minimizing waste due to incorrect brewing or inaccurate packaging labels.

Utilizing these advanced technologies can streamline our operations for greater efficiency while ensuring customer satisfaction by delivering consistently high-quality coffee products. Next up, let’s explore how sustainable practices in coffee production play a role in helping us achieve these goals!

Sustainable Practices In Coffee Production

I’m passionate about revolutionizing coffee production with the latest technology trends and especially excited about sustainable practices. Coffee production has a lot of environmental impacts, so taking steps to reduce those effects is essential. Modern technology can be used to increase efficiency in harvesting and processing coffee and reduce water waste and energy consumption. Implementing green initiatives can help mitigate the environmental impact of coffee production and make it more sustainable for the future.

One example of this is using natural fertilizers instead of synthetic ones. Doing so preserves topsoil quality and reduces the risk of runoff polluting nearby water sources. Additionally, modern technology can be used to detect pests before an infestation begins, helping us avoid using pesticides that harm ecosystems. By leveraging these strategies, we can ensure that coffee production continues to be sustainable while still meeting demand.

The use of technology also helps us track our usage of resources like water and energy. We’re able to create detailed records that allow us to understand our consumption patterns better and make adjustments accordingly. This helps bring down costs while also reducing our environmental footprint at the same time. We’re always looking for ways to improve sustainability in coffee production with new technology advancements, so this is an ongoing process for us here at the company.

These practices are essential for ensuring that the industry remains viable for future generations, but there’s more we can do with modern technology – like blockchain technology in supply chain management – which will help us continue driving innovation in coffee production sustainability initiatives.

Blockchain Technology In Supply Chain Management

Imagine a world where blockchain technology revolutionizes coffee production in its supply chain management. A world in which every step of the process is tracked and monitored, enabling us to create a secure and transparent system that ensures quality control and sustainability. By incorporating blockchain technology into the supply chain management of coffee production, we can ensure that each transaction is documented accurately and securely, leading to increased efficiency, cost savings, and improved overall traceability.

We are now seeing more companies turning to automation technologies such as augmented reality or machine learning algorithms to automate certain parts of the production process. This allows us to reduce labor costs while still maintaining high-quality standards. Additionally, these technologies enable us to optimize our processes to reduce wastage, increase efficiency, and improve customer satisfaction.

The future of coffee production is here and it’s exciting! Blockchain technology has already proven its potential for revolutionizing the industry. As more companies adopt it into their supply chain management strategies, we will be able to reap even greater rewards from this groundbreaking innovation. Now more than ever before is the time for our industry to embrace these new trends in order to ensure a prosperous future for everyone involved in coffee production. With blockchain technology leading the way, we can look forward to an even brighter future full of possibilities for coffee producers around the world.

Looking ahead towards further advancement in coffee production technology, IoT (Internet of Things), sensors and monitoring systems offer great promise for optimizing processes while maintaining quality control standards across all stages of production.

IoT, Sensors, And Monitoring Systems

The Internet of Things (IoT), sensors, and monitoring systems are revolutionizing how coffee production is managed. By utilizing these technologies, coffee producers can leverage various data points to optimize their operations. This data can inform decisions such as harvesting techniques, roasting profiles, and packaging methods.

The list of benefits of incorporating IoT technology into coffee production is extensive:

- Optimize Production:

- Automate processes to reduce waste and improve efficiency in production cycles.

- Monitor machinery performance and make proactive adjustments to maximize output.

- Improve Quality Control:

- Collect sensor data about moisture levels and other environmental conditions for better quality assurance.

- Accurately track product movements throughout the supply chain for enhanced traceability.

- Enhance Visibility:

- Leverage real-time analytics to gain insights into customer preferences and trends.

- Utilize predictive analytics to anticipate future market demands.

These advancements have already dramatically affected how we produce coffee today, allowing us to produce higher quality products with greater efficiency than ever before. With these technologies becoming increasingly accessible, it’s not hard to imagine how they will continue to shape the future of the industry. Augmented reality is now being employed in coffee production as a tool for troubleshooting complex machinery issues quickly and accurately.

Augmented Reality For Troubleshooting

Augmented reality is revolutionizing the way coffee production is managed. It offers a more efficient and accurate way of troubleshooting problems that arise in the process. Augmented reality technology can help quickly locate and identify issues while providing detailed instructions on how to resolve them. This helps minimize downtime, ensuring that production remains consistent and reliable.

The use of augmented reality for troubleshooting also provides an opportunity for coffee producers to take advantage of advanced data analytics. By collecting data about their production processes, producers can gain valuable insights into efficiency, cost savings, and other factors that are critical for success. This data can then be used to create a roadmap for optimizing operations and ensuring long-term profitability.

Finally, by using augmented reality technology for troubleshooting, coffee producers can ensure that their staff is better equipped to handle unexpected problems. With detailed instructions readily available, employees can quickly implement solutions without having to rely on guesswork or manual intervention. This helps improve overall productivity while reducing costly mistakes. All of these benefits make augmented reality an invaluable tool in modernizing coffee production.

Benefits Of Modernizing Coffee Production

I’m often asked why modernizing coffee production is necessary. The answer is simple: it provides numerous benefits to coffee producers. Automation has enabled coffee producers to streamline their operations and increase efficiency while improving quality at the same time.

Benefits Automation Advantages Improved Quality Efficiency Gains Process Optimization Better Taste Profile Reduced Labor Costs Standardized Processes Higher Yields Sustainable Production Less Wastage & Pollution Higher Grading Standards

Efficiency gains reduce labor costs, allowing coffee producers to focus on optimizing their processes for better results. Standardized processes also result in less wastage and pollution, making production more sustainable. Meanwhile improved quality means higher yields, a better taste profile, and higher grading standards – all of which benefit the consumer as well as the producer.

Modernizing coffee production isn’t just about increasing profits or achieving sustainability goals; it’s also about creating a better product that customers can rely on time and time again. Sure, there are upfront costs associated with automation, but the long-term benefits make it an attractive option for any serious coffee producer.

Frequently Asked Questions

What Is The Cost Of Implementing New Technology In Coffee Production?

Implementing new technology into coffee production can be a costly endeavor, but it’s also an important one. To modernize the coffee production process, businesses need to look at the latest trends in technology and understand how they can make improvements. Understanding the cost of implementation is key for organizations looking to increase the efficiency of their operations.

When considering the cost of implementing modern technologies in coffee production, you have to think about more than just financial costs. You must also consider the human resources needed for training and maintenance of any new systems. This means that companies will need to invest in knowledgeable and experienced personnel with this type of technology as well as time for employee education on how to use it properly and efficiently. Additionally, businesses may have to pay licensing fees or purchase additional hardware or software which could add up quickly.

In order to maximize any investments made in modernizing coffee production processes with technology, organizations need to ensure that they weigh all their options carefully and determine what is best for their business needs and goals. This includes researching all available options, understanding what kind of return on investment each option offers, and ensuring that employees are appropriately trained before anything is implemented. Taking these steps can help a business make sure that they are getting the most bang for their buck when investing in technology for their coffee production process.

Is There A Way To Measure The Impact Of Modernizing Coffee Production On The Environment?

The impact of modernizing coffee production on the environment is an important question. As technology advances, it’s essential to measure and understand the environmental effects of these changes. We need to take into account emissions, resource use, and waste in order to effectively assess the environmental impact of modernizing the coffee production process.

There are several ways to measure this environmental impact. For example, we could look at how much energy is being used and compare it to previous energy levels before modernizing. We could also analyze resource usage like water or land use as well as waste generated from the production process. This would give us a comprehensive overview of how modernizing coffee production affects the environment.

In addition, there are various technologies that can be used to reduce our environmental footprint while improving coffee production efficiency. Utilizing renewable energy sources such as solar or wind power, implementing sustainable farming practices, and using digital automation can all help reduce our eco-footprint while helping optimize the entire coffee production cycle. By utilizing these tools and methods, we can ensure that our efforts towards modernizing coffee production are not only efficient but also environmentally friendly.

Are There Any Ethical Considerations When Using Robotics And Ai In Production?

As the coffee production industry continues to evolve, so too must our understanding of ethics when incorporating robotics and artificial intelligence (AI) into production. With automation increasingly becoming a part of modern life, it’s important that we take the time to consider any ethical implications arising from this shift. Coffee production is one area that could be significantly impacted by AI and robotic technology, so it’s crucial for us to understand what ethical considerations are involved.

Robotics and AI can bring many benefits to coffee production, such as greater efficiency and accuracy in operations. However, these technologies can also raise questions about their impact on those who work in the industry. For example, how will automation affect job security? Will workers suffer from decreased wages or fewer opportunities? It’s important for us to understand the potential consequences of using robotics and AI in production before we implement them.

At the same time, it’s essential that we recognize the potential environmental benefits of modernizing coffee production through robotics and AI. Automation can help reduce waste and energy consumption while improving quality control. We must ensure that any new technology is sustainable and ethically sound before introducing it into our coffee production processes. Ultimately, if done responsibly, these new technologies can have positive impacts on both people and the environment; however, we must carefully consider all ethical considerations before making any decisions.

How Is Blockchain Technology Used To Improve The Efficiency Of The Supply Chain?

Have you ever wondered how blockchain technology can be used to improve the efficiency of the coffee production supply chain? As a coffee production technology expert, I’m here to tell you all about it. Automated systems and blockchain are dramatically changing the way we think about coffee production and its supply chain.

Blockchain is a distributed ledger technology that allows for secure and transparent transactions, making it especially useful in the coffee production industry. This technology can be used to track all aspects of the supply chain from farm to cup, allowing for real-time updates on inventory levels and delivery schedules. This can help producers stay on top of their inventory and deliveries, leading to greater efficiency in the long run.

In addition to tracking inventory levels, blockchain technology can also be used to automate payments between producers and retailers. By automating this process, companies can save time and money by eliminating manual processes like invoicing and payment processing. The result is an efficient system that allows for faster payments and better customer service.

Overall, blockchain technology has revolutionized the way companies manage their supply chains in coffee production. It’s allowed for increased efficiency, improved customer service, faster payments, and more transparency throughout the entire process. With these benefits in mind, it’s no wonder why so many businesses are embracing this revolutionary technology as a way to improve their operations.

What Are The Potential Downsides Of Using Automated Systems For Coffee Production?

When it comes to using automated systems for coffee production, there are a few potential downsides that should be taken into account. As an expert in coffee production technology, I’ve identified the following key risks associated with automation:

- Robot malfunctions and errors

- The cost of purchasing and maintaining machines and robots

- Unforeseen consequences of AI algorithms

- Limiting creativity and innovation

Robot malfunctions and errors can cause disruption to the production process, resulting in delays or even an inability to complete orders. Cost is also an issue as robots can be expensive to purchase and maintain, often requiring specialized technicians to keep them running smoothly. Additionally, AI algorithms may have unforeseen consequences when applied to this type of task, leading to unexpected results or unpredictable outcomes. Finally, relying too heavily on automated systems for production can limit innovation and creativity within the industry, reducing the potential for new ideas or products.

Overall, automation offers many benefits in terms of speed and efficiency but it’s important to be aware of its potential drawbacks before investing in any robotic system or machine learning algorithm. It’s essential that businesses understand the risks involved so they can make informed decisions when deciding whether or not automation is right for them.

Conclusion

Implementing modern technology in coffee production can revolutionize the industry and lead to improved efficiency, cost savings and environmental sustainability. To make the most of this revolution, it is important for producers to consider their options when investing in technology carefully.

For example, a major global producer recently implemented automated processes to increase the efficiency and accuracy of their operations. This has enabled them to reduce waste and improve quality control – all while creating a more sustainable coffee production cycle.

However, coffee producers must also take into account ethical considerations when implementing new technology in their operations. Automation and robotics often require significant capital investment and should have clear benefits for both people and planet before they are adopted. The potential downsides of using automated systems must be weighed against the potential gains to ensure that the technology used is beneficial to everyone involved in the process.

Technology offers great potential for revolutionizing coffee production, but it must be done responsibly with a clear understanding of its implications on all stakeholders involved.

Justin is a seasoned author, coffee and tea enthusiast, and an essential member of the Cappuccino Oracle team. With a keen appreciation for the complexities of coffee, coffee alternatives, and tea, Justin has dedicated his professional career to exploring these realms and sharing his insights with readers worldwide.

Justin’s immersion in the world of coffee, coffee alternatives, and tea began at a young age, kindling a passion that extended beyond mere consumption. This love for these beverages led him to combine his talent for writing with his devotion to coffee and tea, bringing him to Cappuccino Oracle as a dedicated author.

Beginners Guides

Achieving Consistent Extraction: The Power of Even Distribution

Did you know that maintaining consistent extraction plays a crucial role in creating top-notch coffee? A critical factor in achieving this uniformity is ensuring the even distribution of coffee grounds. If distribution is uneven, it can result in unbalanced flavors caused by over-extraction in certain areas and under-extraction in others.

Overcoming the challenges of clumping, poor distribution, and inconsistent grind is crucial for a delightful coffee experience. In this article, we will explore the Weiss Distribution Technique (WDT) and its benefits in promoting uniform distribution and minimizing channeling during espresso extraction.

Key Takeaways

- Uneven distribution leads to inconsistent extraction, with over-extraction in some parts and under-extraction in others.

- The Weiss Distribution Technique (WDT) improves the uniformity of coffee grounds distribution and minimizes channeling during espresso extraction.

- Implementing WDT involves stirring the coffee grounds in a circular motion, leveling the coffee bed, and tamping with even pressure.

- WDT offers advantages such as improved extraction consistency, uniform water flow, reduced channeling, and enhanced flavor and aroma.

The Importance of Even Distribution for Consistent Extraction

In the pursuit of consistent extraction, the importance lies in achieving an even distribution of coffee grounds throughout the portafilter. This is because uneven distribution can lead to inconsistent extraction, resulting in over-extraction in some areas and under-extraction in others. To achieve balanced flavors, every particle of coffee grounds must contribute equally to the flavor profile. The science behind even distribution in coffee extraction involves ensuring that water finds the path of least resistance, promoting an even flow through all the coffee grounds.

To achieve even distribution, there are practical tips that can be followed. Firstly, it is important to prevent clumping of the coffee grounds, as clumps can lead to uneven extraction. Secondly, proper distribution and tamping techniques can help prevent channeling, which is the uneven flow of water through the coffee bed. Additionally, using a consistent grind and mastering the technique can also contribute to achieving even distribution.

Challenges in Achieving Perfect Distribution

Achieving perfect distribution of coffee grounds poses several challenges in the pursuit of consistent extraction. These challenges include clumping of coffee grounds, channeling caused by poor distribution or tamping, inconsistent grind from different grinders, and the tricky technique for beginners.

Overcoming these distribution challenges is essential for a delightful coffee experience. Techniques for improving distribution consistency include the Weiss Distribution Technique (WDT), which was introduced by John Weiss. WDT improves the uniformity of coffee grounds distribution, minimizes channeling during espresso extraction, and promotes even water flow by using a thin tool to stir and redistribute grounds.

Other distribution methods such as Stockfleth’s method, tapping method, leveling tools, and shaking method are also compared, but the WDT stands out for its attention to detail and effectiveness in breaking up clumps.

The Weiss Distribution Technique (Wdt) and Its Benefits

One of the notable benefits of the Weiss Distribution Technique (WDT) is its ability to improve the uniformity and consistency of coffee grounds distribution during espresso extraction.

This technique, introduced by John Weiss, has gained traction among baristas and home brewers for its effectiveness in minimizing channeling and promoting even water flow. By using a thin tool to stir and redistribute the grounds, the WDT breaks up clumps and ensures that every particle contributes to the flavor equally.

The advantages of implementing the WDT include improved extraction consistency, reduced channeling, and enhanced flavor and aroma. For beginners using the WDT technique, it is recommended to start simple, focus on consistency, and document the process for refinement over time.

Incorporating the WDT with other techniques can also elevate the coffee quality.

History and Origin of WDT

Since its introduction by John Weiss, the Weiss Distribution Technique (WDT) has evolved from a simple and effective method to a recognized technique used by baristas and home brewers alike. Here is a brief history and origin of the WDT:

-

Online tip to recognized technique: Initially, the WDT gained traction on coffee forums and communities as an effective way to improve uniformity of coffee grounds distribution. It quickly transitioned from a mere online tip to a recognized technique due to its success in minimizing channeling during espresso extraction.

-

Name after its creator: The technique is named after its creator, John Weiss, who introduced it as a simple and effective method for achieving even distribution of coffee grounds.

-

Baristas and home brewers: Over time, the WDT technique has become widely adopted by baristas and home brewers alike. Its effectiveness in breaking up clumps and promoting even water flow has made it a popular choice among coffee enthusiasts.

-

Evolution of the WDT technique: As more people started using the WDT, it has undergone refinements and variations. Baristas and home brewers have experimented with different tools and techniques to further improve the distribution process.

Common misconceptions about WDT: Despite its proven effectiveness, some misconceptions surrounding the WDT technique still exist. These include the belief that it is a complicated and time-consuming process, or that it doesn’t make a noticeable difference in the final brew. However, with proper understanding and practice, the WDT can greatly contribute to achieving consistent extraction and a delicious cup of coffee.

Implementing the WDT: Step-by-Step Guide

To successfully implement the WDT technique, follow this step-by-step guide for achieving even distribution of coffee grounds.

-

First, ensure that the portafilter is clean and ready for use.

-

Next, dose the required amount of coffee into the portafilter basket.

-

Gently stir the coffee grounds in a circular motion using a thin tool, such as a paperclip or toothpick, to break up any clumps and promote uniform distribution.

-

Once the grounds are evenly distributed, level the coffee bed with a flat edge to create a consistent surface.

-

Finally, tamp the coffee with even pressure to further enhance the even distribution.

Frequently Asked Questions

What Are Some Common Misconceptions About Even Distribution in Coffee Extraction?

Common misconceptions about even distribution in coffee extraction include the belief that it is unnecessary or that it doesn’t significantly impact flavor. Techniques for even distribution, such as the Weiss Distribution Technique, are essential for consistent extraction and balanced flavors.

Can the Weiss Distribution Technique Be Used for Other Brewing Methods Besides Espresso?

The Weiss Distribution Technique (WDT) can be used for alternative brewing methods besides espresso. It promotes even extraction, resulting in enhanced flavor and aroma. Its benefits include improved consistency and reduced channeling.

How Does Clumping Affect the Extraction Process and Flavor of the Coffee?

Clumping in coffee grounds affects extraction consistency and flavor. Uneven distribution leads to over-extraction in some parts and under-extraction in others. Techniques like the Weiss Distribution Technique (WDT) improve consistency and enhance the overall coffee experience.

Are There Any Specific Tools or Equipment Required to Implement the Weiss Distribution Technique?

Specific tools for implementing the Weiss distribution technique include a thin tool for stirring and redistributing coffee grounds. Even distribution is crucial for consistent extraction, ensuring uniform water flow and enhanced flavor and aroma.

What Are Some Alternative Methods to Achieve Even Distribution in Coffee Extraction?

Alternative techniques to achieve even distribution in coffee extraction include Stockfleth’s method, tapping method, leveling tools, and shaking method. These methods aim to break up clumps and promote uniform water flow for improved extraction consistency and enhanced flavor.

Conclusion

In the quest for the perfect cup of coffee, achieving consistent extraction is paramount. Even distribution of coffee grounds is key to this process, ensuring that each particle contributes to the overall flavor.

The Weiss Distribution Technique (WDT) has emerged as a powerful method to overcome the challenges of clumping and channeling, promoting uniformity and enhancing the espresso extraction process.

With its history and origin explored, a step-by-step guide provided, and practical tips offered, the WDT proves to be a valuable tool in the pursuit of a delightful coffee experience.

In the vast and diverse world of coffee, coffee alternatives, and tea, Olivia has found her calling. As an author and a dedicated coffee and tea aficionado, her work for Cappuccino Oracle reflects her profound love and understanding of the intricate complexities found within these beverages. Olivia’s passion for the subject serves as both a catalyst for her creativity and a connection point with her audience.

Olivia’s appreciation for coffee, coffee alternatives, and tea blossomed at an early age. She discovered that these beverages invigorated her senses and stimulated her creative spirit. From the nuanced flavors of single-origin roasts to the captivating narratives intertwined with coffee, coffee alternatives, and tea trade and culture, Olivia found an unlimited source of inspiration in her daily cup.

Her love for these beverages and her talent for storytelling eventually converged at Cappuccino Oracle. As an author, Olivia’s mission is to illuminate the intricate tapestry that makes up the world of coffee, coffee alternatives, and tea. Her articles span a diverse range of topics, encompassing everything from the unique flavors of different brews to the sociocultural history intertwined with their cultivation and consumption.

Beginners Guides

How Does The Caffeine Content In Tea And Energy Drinks Affect The Body Differently

The adage ‘You are what you drink’ aptly applies, especially regarding caffeine. This natural stimulant present in tea and energy drinks significantly influences our physiology. However, have you considered the varying effects of caffeine levels in these drinks on our body?

In this article, we will delve into the fascinating world of caffeine and explore its effects on the body.

Firstly, we will examine the caffeine content in tea and energy drinks, comparing the two and highlighting any differences. We will then explore how caffeine is absorbed and metabolized by the body, shedding light on why we may experience varying effects.

From there, we will delve into the effects of caffeine on the brain and nervous system, as well as its influence on heart health. Additionally, we will explore the impact of caffeine on our sleep patterns and discuss personal factors that can affect our sensitivity to this powerful substance.

So grab a cup of tea or energy drink, and let’s dive into the stimulating world of caffeine.

Key Takeaways

- The caffeine content in tea and energy drinks can have different effects on the body.

- Tea typically contains lower levels of caffeine compared to energy drinks, which may result in milder stimulant effects.

- Energy drinks, with their higher caffeine content, may enhance exercise performance and reduce perceived exertion.

- Tea, being lower in caffeine, may have less impact on sleep patterns compared to energy drinks, which can disrupt sleep quality and duration.

Understanding Caffeine’s Effects on the Body

Understanding how caffeine affects the body differently in tea and energy drinks is crucial for comprehending the intricate ways in which these beverages impact our overall well-being.

Caffeine is a stimulant that affects the central nervous system, increasing mental alertness and reducing fatigue. When consumed before exercise, caffeine can improve performance by enhancing endurance, reducing perceived exertion, and increasing fat oxidation. Studies have shown that caffeine can also improve cognitive function, including attention, reaction time, and memory.

However, the effects of caffeine can vary depending on the source. Tea contains lower levels of caffeine compared to energy drinks, but it also contains other compounds like L-theanine, which may have calming effects.

Transitioning into the subsequent section about the caffeine content in tea, it is important to understand how these additional compounds in tea may influence the body differently.

The Caffeine Content in Tea

To truly grasp the impact, imagine how that invigorating cup of tea you enjoy every morning sends a jolt of energy coursing through your veins, making you feel more alive than ever. When it comes to caffeine content, tea usually contains less caffeine than coffee, but the exact amount can vary depending on the type of tea.

Here are three examples:

- Green tea: Contains around 20-45 mg of caffeine per 8-ounce serving.

- Black tea: Typically has 40-70 mg of caffeine per 8-ounce serving.

- Herbal tea: Usually caffeine-free, but some varieties like yerba mate may contain small amounts.

Knowing the caffeine levels in different types of tea can help you make informed choices about your daily caffeine intake.

Now, let’s delve into the caffeine content in energy drinks.

The Caffeine Content in Energy Drinks

Imagine the electrifying surge of energy that rushes through you with every sip of those fizzy, vibrant drinks you can’t resist. Energy drinks are known for their high caffeine content, which is one of the main ingredients that gives you that instant boost.

In fact, energy drinks typically contain much higher levels of caffeine compared to tea. While a cup of tea usually contains around 30-50 milligrams of caffeine, energy drinks can have anywhere from 80 to 300 milligrams per serving.

Such high levels of caffeine in energy drinks can potentially lead to caffeine overdose if consumed excessively. It is important to be mindful of your caffeine intake and not exceed the recommended limits.

Now, let’s delve into the absorption and metabolism of caffeine, and how it affects our bodies.

Absorption and Metabolism of Caffeine

The electrifying surge of energy you feel after consuming energy drinks is due to the rapid absorption and metabolism of caffeine in your body.

When you drink an energy drink, the caffeine is quickly absorbed into your bloodstream through the lining of your stomach and small intestine. From there, it is transported to your liver, where it undergoes various metabolic pathways. One of these pathways involves the enzyme cytochrome P450 1A2, which breaks down caffeine into three primary metabolites: paraxanthine, theobromine, and theophylline.

Each of these metabolites has its own effects on the body, contributing to the overall physiological response to caffeine. The absorption rate and metabolism of caffeine can vary from person to person, depending on factors such as age, genetics, and liver function.

Understanding how caffeine is absorbed and metabolized is crucial in understanding its effects on the brain and nervous system.

Effects of Caffeine on the Brain and Nervous System

Get ready to experience a surge of energy as caffeine zips through your bloodstream, activating your brain and nervous system. Caffeine has profound effects on memory and cognitive function, enhancing alertness and improving attention span. Studies have shown that it can enhance short-term memory and improve overall cognitive performance. However, excessive caffeine consumption may lead to anxiety and restlessness, as it stimulates the release of adrenaline, a hormone that triggers the body’s "fight or flight" response. In addition, caffeine can also affect mood by increasing dopamine levels, which can improve feelings of well-being and happiness. Nevertheless, it’s important to note that individual responses to caffeine vary, and excessive consumption can lead to negative effects such as jitteriness and insomnia. Transitioning into the subsequent section about the ‘impact on heart health’, caffeine not only affects the brain, but also has implications for cardiovascular health.

Impact on Heart Health

When it comes to the impact of caffeine on heart health, it’s important to consider its effect on heart rate and blood pressure. Caffeine has been shown to temporarily increase both heart rate and blood pressure, which can be concerning for individuals with pre-existing cardiovascular conditions.

Additionally, long-term consumption of caffeine has been associated with an increased risk of cardiovascular issues, such as heart disease and hypertension. These findings highlight the need for moderation and awareness when it comes to caffeine intake and its potential impact on our heart health.

Caffeine’s Effect on Heart Rate and Blood Pressure

Contrarily, sipping on a cup of tea or chugging an energy drink can have contrasting effects on your heart rate and blood pressure. While both tea and energy drinks contain caffeine, their effects on the cardiovascular system differ. Here are five key points to consider:

Tea has a moderate amount of caffeine, which can slightly increase heart rate and blood pressure. However, these effects are usually short-lived and not significant enough to cause concern.

Energy drinks, on the other hand, often contain high levels of caffeine, which can lead to a more pronounced increase in heart rate and blood pressure. This can be especially problematic for individuals with underlying heart conditions.

Caffeine’s impact on exercise performance varies. Some studies suggest that moderate caffeine consumption can enhance endurance and performance, while excessive intake may lead to negative effects.

Tea is a hydrating beverage, contributing to overall hydration levels. Energy drinks, due to their caffeine content, can have a diuretic effect, potentially increasing the risk of dehydration.

Considering the long-term effects on cardiovascular health, excessive consumption of energy drinks, with their high caffeine content and added ingredients, may pose a greater risk compared to moderate tea consumption.

With these considerations in mind, let’s explore the long-term effects on cardiovascular health.

Long-Term Effects on Cardiovascular Health

The long-term impact of regular consumption of caffeine-containing beverages on cardiovascular health is worth exploring. Research suggests that excessive intake of caffeine can have adverse effects on the cardiovascular system. Studies have shown that long-term consumption of high doses of caffeine can lead to increased risk of cardiovascular diseases such as hypertension, heart rhythm disorders, and even heart attacks. Additionally, caffeine has been found to have negative effects on cognitive function in the long term. It can impair memory, attention, and overall cognitive performance. On the other hand, caffeine has been shown to have a positive impact on exercise performance. It can enhance endurance, reduce perceived exertion, and improve overall athletic performance. These findings highlight the importance of moderation when consuming caffeine-containing beverages for long-term cardiovascular health and cognitive function. Moving on to the next section, let’s explore caffeine’s influence on sleep patterns.

Caffeine’s Influence on Sleep Patterns

Caffeine’s impact on sleep patterns can disrupt the body’s natural rhythm and lead to restless nights. Research shows that consuming caffeine, whether from tea or energy drinks, can affect the quality and quantity of sleep.

Caffeine’s influence on cognitive function is well-documented, with studies suggesting that it can improve alertness and concentration. However, when it comes to sleep, caffeine acts as a stimulant that can delay the onset of sleep and reduce overall sleep duration. This can have significant implications on athletic performance, as sleep is crucial for recovery and optimal physical functioning.

It’s important to note that individual sensitivity to caffeine varies, with some people being more affected by its sleep-disrupting effects than others. Transitioning into the next section, personal factors and sensitivity to caffeine play a role in determining how individuals respond to its effects without needing to take a step.

Personal Factors and Sensitivity to Caffeine

When it comes to caffeine, everyone is different in terms of their tolerance and sensitivity. Some people may be able to handle large amounts of caffeine without feeling any negative effects, while others may be more sensitive and experience jitters, anxiety, or trouble sleeping even with small amounts.

These individual differences in caffeine sensitivity can be influenced by various factors, including genetics. Research has shown that certain genetic variations can affect how our bodies process and metabolize caffeine, which can ultimately impact our response to it.

Individual Tolerance and Sensitivity

Feeling tired? Did you know that your individual tolerance and sensitivity can determine how caffeine affects your body differently in tea and energy drinks? Everyone has a unique response to caffeine based on their individual tolerance and sensitivity levels. Some people may be more sensitive to caffeine and experience its effects more strongly, while others may have a higher tolerance and not feel the same impact. Factors such as age, weight, metabolism, and overall health can influence individual tolerance and sensitivity. Understanding your own caffeine tolerance can help you make informed decisions about consuming tea or energy drinks.

In the next section, we’ll explore how genetic variations in caffeine processing can also play a role in how our bodies react to caffeine.

Genetic Variations in Caffeine Processing

Genetic variations can play a role in how our bodies react to caffeine, but how exactly do these variations impact our response? Well, when it comes to caffeine metabolism, certain genetic variations can affect how quickly or slowly our bodies break down and eliminate caffeine. This can ultimately influence our sensitivity to caffeine and how it affects us.

One key genetic variation that has been studied is in the gene CYP1A2, which is involved in caffeine metabolism. People with certain variations in this gene may metabolize caffeine more slowly, leading to higher levels of caffeine in their system and potentially increased sensitivity to its effects. On the other hand, individuals with faster caffeine metabolism may experience a reduced sensitivity to caffeine.

To illustrate the potential impact of genetic variations on caffeine metabolism, consider the following table:

| Genotype | Caffeine Metabolism Speed | Caffeine Sensitivity |

|---|---|---|

| Slow metabolizer | Slow | Increased |

| Fast metabolizer | Fast | Reduced |

This table demonstrates the potential relationship between genetic variations in caffeine metabolism, caffeine sensitivity, and the speed at which caffeine is broken down in the body. While genetic variations are just one piece of the puzzle, they can contribute to individual differences in how caffeine affects us.

Frequently Asked Questions

Can caffeine in tea and energy drinks cause dehydration?

Yes, caffeine in tea and energy drinks can cause dehydration. It acts as a diuretic, increasing urine production. This can lead to fluid loss and potentially impact cognitive function and sleep quality.

Is it true that caffeine can enhance athletic performance?

Yes, it is true that caffeine can enhance athletic performance. Caffeine increases caffeine metabolism, which can lead to improved endurance and reduced fatigue. It also has stimulant effects that can increase heart rate during exercise.

Are there any long-term effects of consuming high levels of caffeine?

Consuming high levels of caffeine can have long-term health risks such as heart problems and addiction. Additionally, it can negatively impact sleep quality, leading to insomnia and restlessness.

Does the caffeine content in tea and energy drinks affect weight loss or weight gain?

The caffeine content in tea and energy drinks can affect weight loss or weight gain. It can enhance metabolism and increase calorie burning, potentially aiding in weight management. However, other factors such as diet and exercise also play a crucial role.

Can caffeine withdrawal symptoms occur when reducing or stopping the consumption of tea and energy drinks?

Experiencing caffeine withdrawal symptoms, like headaches and fatigue, is common when reducing or stopping the consumption of tea and energy drinks. These symptoms can also disrupt sleep quality, making it harder to get a good night’s rest.

Conclusion

In conclusion, the caffeine content in tea and energy drinks affects the body differently based on factors such as absorption, metabolism, and individual sensitivity.

While both beverages contain caffeine, the higher levels found in energy drinks can lead to increased alertness and energy levels. On the other hand, the lower caffeine content in tea allows for a more gradual and sustained release of energy.

For instance, a case study conducted on individuals who consumed energy drinks showed a significant increase in heart rate and blood pressure, while those who consumed tea experienced a more moderate and manageable effect on their cardiovascular system.

Arf, an author and an innovative enthusiast of coffee, coffee alternatives, and tea, plays a crucial role as a contributor to the esteemed Cappuccino Oracle platform. Renowned for his curiosity and passion for these captivating beverages, Arf has carved out a unique space for himself in the world of exploration and writing. He realized that coffee, coffee alternatives, and tea are not mere drinks to keep one awake, but universes of flavors and stories waiting to be explored.

Arf’s articles for Cappuccino Oracle blend meticulous research with personal experiences, providing readers with an in-depth understanding of various types of coffee, coffee alternatives, and tea, along with their unique characteristics, cultures, and histories. His honest reviews and engaging narratives guide readers on their own journeys, helping them discover their preferences and find their perfect brew.

Beginners Guides

How Does The Caffeine Content In Tea Change With Different Brewing Methods

Sitting here, enjoying my warm tea, I find myself curious about how the caffeine levels in my drink alter with various brewing techniques. It’s intriguing to consider that just altering the way we make our tea could significantly change the caffeine content we ingest.

In this article, we will delve into the world of tea and explore how different brewing techniques can alter the caffeine levels in our favorite beverage.

Tea, as we know, contains caffeine, a natural stimulant that gives us that much-needed energy boost. But did you know that the amount of caffeine extracted from tea leaves can vary depending on factors such as steeping time, water temperature, and even the type of tea?

By understanding these variables and their effects on caffeine extraction, we can gain insight into how to control our caffeine intake and tailor our tea-drinking experience to our preferences.

So, let’s embark on this scientific journey together, as we uncover the secrets behind the caffeine content in tea and discover how different brewing methods can influence it.

Key Takeaways

- Different brewing methods can significantly impact the caffeine content in tea.

- Longer brewing time and hotter water tend to increase the caffeine content in tea.

- Shorter brewing time and cooler water can help reduce the amount of caffeine in tea.

- Herbal teas, such as chamomile and peppermint, are caffeine-free alternatives to traditional tea.

Understanding Caffeine in Tea

If you want to fully understand the caffeine content in tea, you’ll have to delve into the intricate relationship between brewing methods and the resulting levels of this stimulating compound.

The amount of caffeine in tea can vary depending on several factors, including the type of tea leaves used, the brewing time, and the water temperature. Caffeine metabolism also plays a role, as individuals with a higher metabolism may process caffeine more quickly than others. Additionally, caffeine sensitivity varies among individuals, with some people being more sensitive to its effects than others.

Scientific studies have shown that brewing methods such as steeping time and water temperature can significantly impact the caffeine content in tea. These factors affect the extraction process and can result in higher or lower caffeine levels.

Transitioning to the next section, let’s explore the impact of different brewing methods on caffeine content in tea.

Impact of Different Brewing Methods

Surprisingly, the way you brew your tea can have a significant effect on the amount of caffeine it ends up containing. Temperature control and brewing time variations play a crucial role in determining the caffeine content in your cup of tea.

When it comes to temperature, higher temperatures generally result in more caffeine extraction. For example, using boiling water can lead to a greater release of caffeine compared to using lower temperatures.

Similarly, brewing time also affects caffeine extraction. Longer brewing times tend to extract more caffeine from the tea leaves, while shorter brewing times result in lower caffeine content.

Understanding these factors and their impact on caffeine extraction is essential for controlling the caffeine levels in your tea. Transitioning into the subsequent section about ‘factors affecting caffeine extraction’, it is important to consider other variables that influence this process.

Factors Affecting Caffeine Extraction

To truly understand the factors that impact the extraction of caffeine, you must delve into the intricacies of your brewing process. Two key factors that affect caffeine extraction in tea are temperature and steeping time.

The temperature of the water used for brewing has a significant effect on the amount of caffeine extracted. Higher temperatures tend to extract more caffeine, while lower temperatures extract less.

Additionally, the length of time the tea leaves are steeped in hot water also influences caffeine extraction. Longer steeping times generally result in higher caffeine content.

These effects of temperature and steeping time on caffeine extraction can vary depending on the type of tea and its specific characteristics.

Moving forward to the subsequent section about caffeine content in black tea, we can explore how these factors play a role in determining its caffeine levels.

Caffeine Content in Black Tea

Black tea, known as the energizing elixir, holds within its depths the secrets of a stimulating experience. When it comes to caffeine extraction in black tea, the brewing method plays a crucial role in determining the caffeine content. Different tea varieties also have varying levels of caffeine. To understand this better, let’s take a look at the table below:

| Tea Variety | Caffeine Content (mg) |

|---|---|

| Assam | 50-90 |

| Darjeeling | 30-70 |

| Earl Grey | 20-60 |

| English Breakfast | 40-80 |

| Ceylon | 30-60 |

As we can see, the caffeine content in black tea can range from 20 to 90 mg, depending on the variety and brewing method. This information is important for those who want to control their caffeine intake or prefer a milder or stronger cup of tea. Moving on to green tea, a popular alternative to black tea, we will explore how its caffeine content compares in the next section.

Caffeine Content in Green Tea

With its refreshing and invigorating properties, green tea offers a delightful alternative to black tea that’ll leave you feeling rejuvenated. Green tea is known for its numerous health benefits, including its high antioxidant content and potential to aid in weight loss.

When it comes to caffeine content, green tea generally contains less caffeine than black tea. However, the levels of caffeine in green tea can vary depending on factors such as the type of green tea leaves used and the brewing method employed. Some studies suggest that consuming green tea can promote weight loss by increasing metabolism and fat oxidation.

While green tea may contain less caffeine than black tea, it still provides a gentle energy boost.

Moving on to the subsequent section about caffeine content in white tea, we’ll explore another intriguing aspect of tea brewing.

Caffeine Content in White Tea

You’ll be surprised to find that white tea packs a punch with its subtle but energizing qualities, making it a perfect choice for those seeking a milder caffeine boost. When it comes to caffeine extraction techniques, white tea differs from green tea. White tea is made from the young buds and leaves of the Camellia sinensis plant, which undergo minimal processing. This minimal processing allows for a higher retention of caffeine compared to other types of tea. Additionally, the caffeine content in white tea can be affected by steeping time. Studies have shown that longer steeping times can lead to higher caffeine extraction from white tea leaves. To better understand this, refer to the table below which showcases the caffeine content in white tea at different steeping times:

| Steeping Time (minutes) | Caffeine Content (mg) |

|---|---|

| 1 | 15 |

| 2 | 25 |

| 3 | 35 |

| 4 | 45 |

| 5 | 55 |

Considering the caffeine extraction techniques and the effect of steeping time on caffeine content, it is evident that white tea offers a range of caffeine levels depending on personal preference. Moving forward, let’s explore the caffeine content in herbal tea.

Caffeine Content in Herbal Tea

Discover the invigorating world of herbal tea and experience the delightful array of flavors that can be enjoyed without worrying about the impact of caffeine on your system.

Herbal teas are naturally caffeine-free, making them an excellent choice for those looking to avoid the stimulating effects of caffeine. While the benefits of caffeine in tea include improved focus and increased energy, some individuals may be sensitive to its effects or prefer to limit their intake.

Fortunately, there are numerous decaffeinated herbal tea options available that allow you to enjoy the soothing qualities of tea without the caffeine. These teas are often made from herbs and botanicals that offer their own unique health benefits.

So, if you’re looking for a caffeine-free alternative to traditional teas, explore the world of herbal teas and discover a variety of flavors that can enhance your well-being.

Transitioning into the subsequent section about ‘tips for controlling caffeine intake,’ it’s important to be aware of the different brewing methods that can affect the caffeine content in tea.

Tips for Controlling Caffeine Intake

If you thought controlling your caffeine intake was an easy task, think again – there’s a whole world of unexpected ways to unintentionally consume more caffeine than you realize. When it comes to managing caffeine levels, there are a few tips that can help you stay in control.

First, be aware of the brewing time and temperature when making tea. The longer the brewing time and the hotter the water, the higher the caffeine content will be. So, if you’re looking to reduce your caffeine intake, consider brewing your tea for a shorter period of time and using slightly cooler water.

Additionally, if you’re looking for alternatives to tea, there are several options available. Herbal teas, such as chamomile or peppermint, are naturally caffeine-free and can be a great choice for those looking to reduce their caffeine intake. Other alternatives include decaffeinated tea or non-caffeinated beverages like herbal infusions or fruit juices.

By being mindful of your brewing methods and exploring alternative options, you can effectively manage your caffeine intake.

Frequently Asked Questions

Can the caffeine content in tea vary depending on the brand or type of tea?

Yes, the caffeine content in tea can vary depending on the brand or type of tea. Different brands and types of tea have different levels of caffeine due to variations in processing and growing conditions. Additionally, brewing techniques can also affect the caffeine content in tea.

Are there any health benefits associated with consuming caffeine in tea?

There are potential health benefits associated with consuming caffeine in tea. However, it is important to consider the recommended daily intake and potential risks, as excessive caffeine consumption can lead to negative effects on health.

Does the temperature of the water used for brewing tea affect the caffeine content?

Water temperature significantly affects the extraction of compounds in tea. Higher temperatures release more caffeine and other flavor compounds, resulting in a stronger and more robust flavor. Lower temperatures produce a more delicate and milder flavor.

Can the length of time tea is brewed impact the amount of caffeine extracted?

The length of time tea is brewed can have an impact on the amount of caffeine extracted. Studies suggest that longer brewing times result in higher caffeine content. However, the optimal brewing time for maximum caffeine content varies depending on the type of tea.

Is it possible to completely remove caffeine from tea through various brewing methods?

Removing caffeine from tea is possible through various brewing methods, such as using solvents or carbon dioxide. These methods extract caffeine while preserving the flavor of the tea. However, the effectiveness of decaffeination varies depending on the technique used.

Conclusion

In conclusion, it’s evident that the caffeine content in tea is greatly influenced by various brewing methods. Through careful examination and analysis, it’s clear that factors such as temperature, steeping time, and tea type all play a significant role in the extraction of caffeine.

Whether you prefer a bold black tea or a soothing herbal blend, understanding the caffeine content can help you make informed choices. So next time you brew a cup of tea, remember to take into account these factors to control your caffeine intake.

Knowledge is power, and with this knowledge, you can truly savor your cup of tea.

Arf, an author and an innovative enthusiast of coffee, coffee alternatives, and tea, plays a crucial role as a contributor to the esteemed Cappuccino Oracle platform. Renowned for his curiosity and passion for these captivating beverages, Arf has carved out a unique space for himself in the world of exploration and writing. He realized that coffee, coffee alternatives, and tea are not mere drinks to keep one awake, but universes of flavors and stories waiting to be explored.

Arf’s articles for Cappuccino Oracle blend meticulous research with personal experiences, providing readers with an in-depth understanding of various types of coffee, coffee alternatives, and tea, along with their unique characteristics, cultures, and histories. His honest reviews and engaging narratives guide readers on their own journeys, helping them discover their preferences and find their perfect brew.

-

Americano4 weeks ago

Americano4 weeks agoHow to Make Americano With Moka Pot

-

Americano2 weeks ago

Americano2 weeks agoHow to Make Korean Iced Americano

-

Americano4 weeks ago

Americano4 weeks agoHow to Make Iced Americano With Instant Coffee

-

Americano4 weeks ago

Americano4 weeks agoHow to Make Americano With Bialetti

-

Americano4 weeks ago

Americano4 weeks agoHow to Make Dutch Bros Americano

-

Americano6 days ago

Americano6 days agoHow to Make an Iced Americano With Nespresso

-

Americano2 weeks ago

Americano2 weeks agoHow Many Shots of Espresso for 16 Oz Americano

-

Turmeric Tea1 week ago

Turmeric Tea1 week agoTurmeric Saffron Tea